Go faster and further in analysis with a global “bottom-up” approach

October 28, 2024

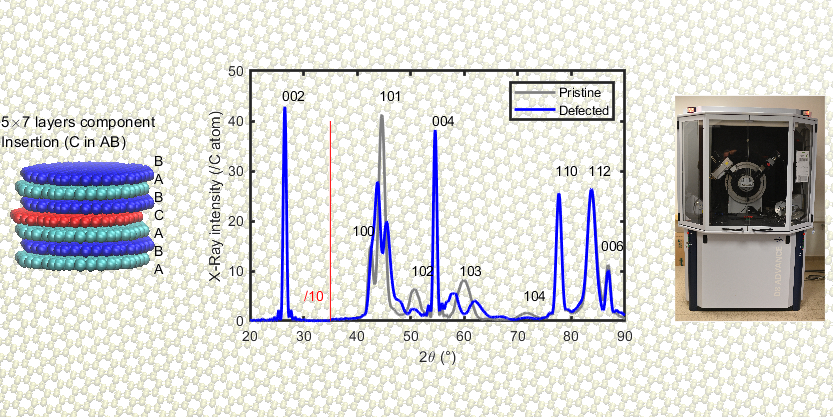

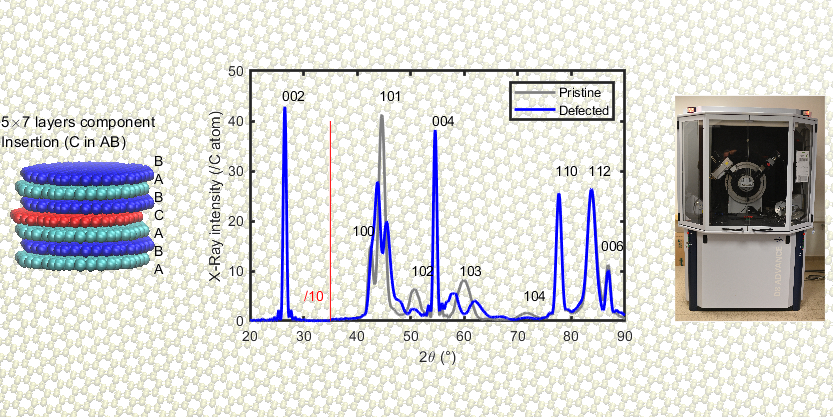

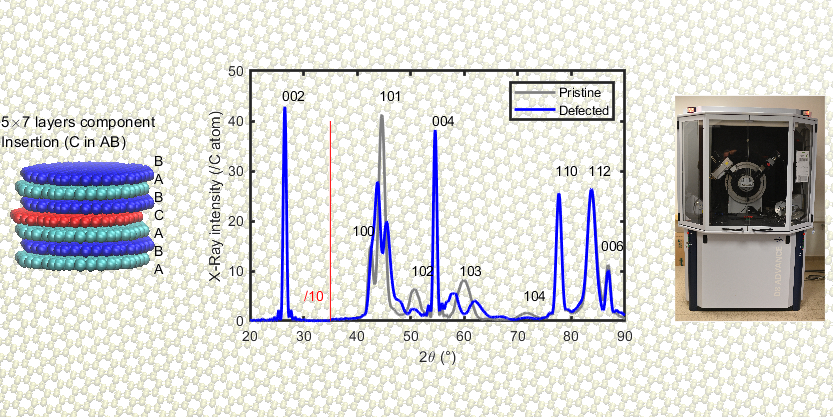

Switching from CPU to GPU and, in the future, to AI, will enable to describe more accurately the description of X-ray diffraction peaks of lamellar carbon compounds ranging from turbostratic carbon to graphite. Where discrepancies existed, and where some signatures were misunderstood, the “bottom-up” approach completed by the generation of fitting functions explains the smallest details of diffractograms, based on interference effects.

For several years now, CEMES has been developing a new approach based on a bottom-up approach combined with adjustment functions first managed by CPU and then GPU to analyse the diffractograms of graphitisable carbons, which are lamellar materials with the particularity of being distributed along a structural continuum.

The diffractograms have signature shapes that are not taken into account by conventional analysis softwares, including subtle interference effects due to the complexity of the stacking sequences in the elementary crystallite. We have identified the specific component of the crystallites responsible for these misunderstood signatures for intermediate crystallisation states: pairs of AB-stacked graphenes separated from the other components by rotational disorders, which strongly modify the 10(0) and 11(0) zones of the diffractograms. Taking them into account resolves all the discrepancies unexplained over the last 80 years, and gives a coherent set of characteristics derived from an analysis based on parameterised functions. For carbons closer to graphite, it is stacking faults that are responsible for the deviations from standard (and unrealistic) models [1], but analysing their influence on the whole diffractograms is now an impossible task without the use of AI.

The latest development in the saga that began in research 10 years ago and started being published 5 years ago [2] involved looking at disordered carbons to elucidate a small-angle peak that had remained unexplained to this day [3]. The tools developed can easily be applied to all diffractograms, as we are now doing on a routine basis ([4] and forthcoming articles). Thanks to the GPU, it is already possible to get away from the relative but deceptive comfort of empiricism! The impact on the community is significant. An important step has been taken: the method is now sufficiently validated for the tools developed to be made available to anyone (https://github.com/PascalPuech/X_Ray). The completion of the full analysis of experimental diffractograms of all types of carbon will come over the long term from artificial intelligence, which will be based on a gigantic database of calculated diffractograms.

Contact:

Pascal Puech | pascal.puech[at]cemes.fr

Publications:

[1] Addressing the effect of stacking faults in X-ray diffractograms of graphite through atom-scale simulations

P. Puech, M. Jeanningros, D. Neumeyer, and M. Monthioux

Carbon Trends 13 (2023) 100311.

DOI: https://doi.org/10.1016/j.cartre.2023.100311

[2] New insight on carbonisation and graphitisation mechanisms as obtained from a bottom-up analytical approach of X-ray diffraction patterns

P. Puech, A. Dabrowska, N. Ratel-Ramond, G. Vignoles, M. Monthioux

Carbon 147 (2019) 602-611.

[3] Specific X-Ray, Raman and TEM signatures of cellulose-derived carbons

K. Mubari, T. Beguerie, M. Monthioux., E. Weiss-Hortala, A. Nzihou., and P. Puech

‘C‘ 8 (2022) 4.

[4] Analysing the modifications of carbon black and other fillers after pyrolysis of model tyres

P.K. Mubari, E. Weiss-Hortala, M. Monthioux, S. Moyano, A. Bowles, G. Fowler, L. Moulin, and P. Puech

Sustainable Materials and Technologies 40 (2024) e00904.

DOI: https://doi.org/10.1016/j.susmat.2024.e00904