The “Physics of Plasticity and Metallurgy” (PPM) group of CEMES aims at understanding the mechanical properties of mainly metallic materials. The research is based on the observation and modeling of the elementary mechanisms of plasticity (behavior of dislocations, phase transformations, diffusive processes, etc.) among others, in connection with the aging of these materials, and the processes of elaboration of which the flash sintering.

The aim of this work is to transpose this knowledge to the optimization of the structural or mechanical qualities of industrial materials with complex microstructure, in particular those of the aeronautical industry.

The privileged tool is the Transmission Electron Microscope, in all the advanced modes of observation, and with the originality of the expertise of the in-situ observation of the behavior of materials stressed in temperature and in stress, at the microscopic or nanoscopic scale.

Marc Legros, group leader

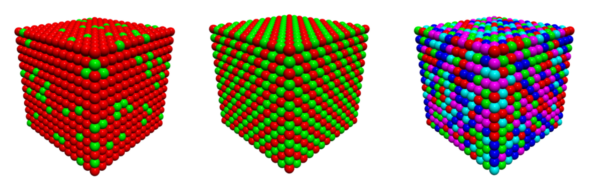

High entropy alloys or multiple principal element alloys (MPA) appeared in the literature in 2004 thanks to two publications by Cantor and Yeh. They differ from “classical” alloys (left, containing a small quantity of solute atoms) and intermetallic alloys (center) in that they consist of several metallic elements (5 at the beginning of their discovery but up to 3 today) that are mixed in equal or nearly equal proportions. The result is a single phase solid solution alloy in which the atoms are supposed to be randomly distributed on an fcc or bcc lattice.

This randomness results in high resistance to deformation. We use in situ TEM to probe this random landscape using dislocations in a large range of temperature in both Cantor type alloys (CoCrFeMnNi) and refractory alloys (HfNbTaTiZr).

Marc Legros, Frédéric Mompiou

We seek to understand why the mechanical properties of alloys are much better than those of pure metals. For example, a ferritic steel is much stronger than pure iron, although their crystal structures are similar. In addition to the effect of precipitates and other hardening phases, the alloy atoms that are dispersed in the metal (said to be in “solid solution”) play an essential role that is particularly difficult to understand. Starting from a pure metal such as iron (cubic centered structure) or zirconium (hexagonal structure), we study the combined effects of various solutes (carbon, oxygen, silicon, nickel, etc.) on the behavior of dislocations observed “in situ” in an electron microscope.

Daniel Caillard, Marc Legros, Frédéric Mompiou

In the absence of dislocations, which are the main carrier of plastic deformation, grain boundaries can compensate for this absence by mechanisms that are currently the subject of intense research worldwide. One critical mechanism is called grain boundary migration by shear coupling. Active at high temperature or in small-grained materials devoid of dislocations, we study this mechanism both using in situ TEM, and molecular dynamics (Collaboration with N. Combe – SiNano group of CEMES).

Since 2013, 3 theses and an ANR project (Rodin) have contributed to establish the critical role of disconnections, a defect consisting of a step and a dislocation and belonging only to grain boundaries. We have shown for instance that the coupling factor (which measures the efficiency of the shear-coupling mechanism by giving the ratio between the shear and the migration distance) depends on these defects rather than on the character of the grain boundary.

A collaboration with D. Texier (ICA) is also in progress to evaluate the influence of grain boundaries in the oxidation kinetics of structural alloys (based on Ti, Ni). Nanoindentation mapping, TEM and DIC are the main investigation tools for this study, supported by an ERC grant (HT-S4DefOx-link).

Marc Legros, Frédéric Mompiou

The metallic materials we use are composed of crystalline grains whose size is a few micrometers. However, it is now possible to develop nanocrystalline materials (grain size less than 100 nm) or ultrafine grains (grain size less than 1 µm).

At this scale, new physical properties appear: from a mechanical point of view, for example, metallic materials with nano-grains have a yield strength up to 10 times higher than their micrometric grain equivalents.

It is therefore understandable that these objects are of interest both at the fundamental and applied levels. This increased mechanical strength is partly explained by the confinement of dislocations whose movement ensures the plastic deformation of the crystals in a large stress and temperature range.

Marc Legros, Frédéric Mompiou, coll. Nicolas Combe (SiNano group of CEMES)

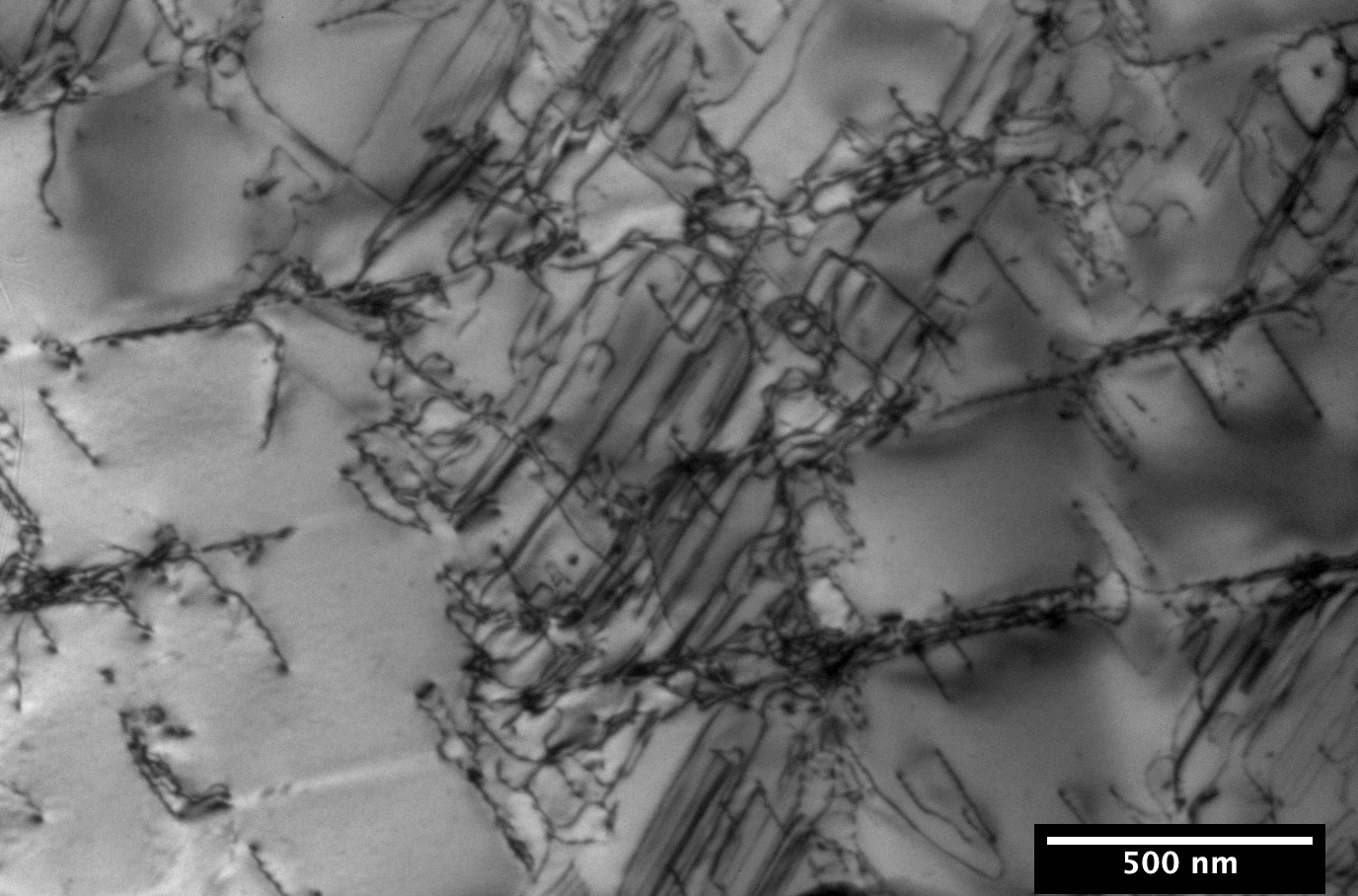

Nickel-based superalloys (Ni-based solid solutions containing other chemical elements such as Cr, Co, Mo, W, Al, Ti, Re, …) are widely used for aircraft engine components, more specifically high-pressure turbine blades, vanes and disks. In particular, the use of single crystal nickel-based superalloys in blades is necessary due to the range of stresses applied to these parts, from intermediate temperatures (700 – 800 °C) and high stresses in the blade root, to high temperatures (1000 – 1200 °C) and low stresses.

The design of new superalloys is essential to achieve higher operating temperatures. Different nickel-based superalloys have been defined by varying the content of alloying elements, in particular the refractory elements Mo, W, Re, Ru and Ta, in order to meet several requirements.

The research activities carried out at CEMES in this field consist in analyzing the microstructures and the deformation micromechanisms in different superalloys to identify the physical parameters related to the chemical compositions of the alloys. The final objective is to interpret the macroscopic mechanical behavior (tensile behavior, creep, fatigue) and to identify the differences in mechanical properties to contribute to the scientific adventure of developing alloys for aerospace.

J. Douin, M. Hantcherli, F Pettinari-Sturmel.

Collaborations : J. Cormier, P. Villechaise, Institut PPrime Poitiers; N. Bozzolo CEMEF Sophia Antipolis.

Image: MET observation of dislocations in the TROPEA superalloy (Patent No US 2021/0214822 A1, J. Cormier, J. Rame, Pprime-SAFRAN) – Thesis University of Toulouse B. Mansoz

Structural precipitation is one of the most effective ways to improve the mechanical properties of metal alloys where the need to lighten structures to limit energy consumption imposes very significant increases in mechanical performance… In this perspective, aluminum alloys remain very good candidates for structural applications. Our studies focus on the determination of the microstructural characteristics of the nanoprecipitates at the origin of the remarkable properties of these alloys but also on their evolution as a function of time and temperature, their aging.

J. Douin, F. Pettinari-Sturmel

Wire-based additive manufacturing is of great interest for the mass production of large metallic aeronautical parts, in particular for titanium alloys. Nevertheless, this technology generates a specific thermal history which leads to singular and original microstructures compared to traditional processes, and which has a direct impact on the mechanical properties.

A fine multi-scale characterization allows to understand the conditions of microstructure formation. The most remarkable aspect is the microstructural gradient created during deposition, with a clear influence of the microstructural heterogeneity on the distribution of plastic deformation.

Our objective is to determine the relationship between the atypical thermal history and the fine microstructure of these titanium alloys, in order to derive the optimal manufacturing conditions with respect to mechanical properties.

J. Douin, F. Pettinari-Strurmel

TiAl intermetallic alloys are industrial materials for high-temperature applications, due to their low density and high mechanical strength when hot. The first industrializations took place in 2011 and 2014 in the last stages (the least constrained) of turbines of aeronautical engines of General Electric and Safran. The objective is now to install these materials in the more upstream stages of engines, i.e. stages working at higher temperatures.

In this industrial context, our team is working on physics issues related to both the elaboration processes of this type of alloys and the understanding of plasticity mechanisms in this family of materials with rich and complex microstructures.

It holds two patents on the development of a TiAl alloy by the powder metallurgy method known as Flash Sintering, which is currently the most efficient for temperatures above 800°C. In addition, in situ TEM, one of the strong points of the PPM group, allows it to analyze in a unique way the deformation mechanisms at the scale of dislocations which are at work in the various crystallographic phases involved as well as at the numerous and varied interfaces.

Alain Couret, Muriel Hantcherli, Guy Molénat, Jean-Philippe Monchoux

The metallization of power modules used in power electronics (automotive, train, home automation, …) is one of the weakest links of these components. Therefore, it limits their reliability and lifetime. We study how the thermomechanical stresses that these devices undergo lead to their failure by mechanisms specific to the metal (Al/Cu) or to the wire bonds. Thanks to collaborations with NXP or Mitsubishi Electric, we have developed specific procedures using TEM, FIB, and nanoindentation techniques to follow the changes in the microstructures of the metal, the wire and their interface in order to decipher the critical mechanisms that lead to their degradation.

M. Legros, L. Karanja

As nuclear energy is one of the ways to reduce our carbon footprint, we are studying, in close collaboration with the CEA (Saclay, Cadarache), the behavior of materials used to produce energy (UO2) or structural materials (Zr, steels, …). Their mechanical behavior under these extreme conditions (irradiation, temperature, corrosion and stress) is once again the focus of concern because they have a direct impact on their life span and that of the power plants in which they are used. In particular, we study how irradiation defects (loops, clusters) interact with dislocations or grain boundaries.

In the case of solar energy (CEA INES collaboration, IM2NP Marseille), the objective is to understand the solidification processes of silicon, the first light/electricity transformer. In this case, the formation of certain dislocation structures such as sub-grain joints or Lomer locks are detrimental to energy conversion and must be avoided. However, how they form during solidification is not yet fully understood. In particular, the role of residual stresses and the process of low-angle grain boundary multiplication are critical.

In the case of structural materials, we are interested in plasticity mechanisms influenced by high temperature irradiation (under operating or storage conditions). Questions about the elementary mechanisms involving dislocation loops formed by the accumulation of point defects during irradiation and mechanical stress still remain poorly understood. We are currently working in collaboration with CEA Saclay (SRMA and SRMP) on studies coupling numerical simulations (Dislocation Dynamics, Molecular Dynamics, and Monte-Carlo kinetics on Objects) and in-situ TEM (under stress and/or temperature) in order to to better understand the mechanisms of irradiation creep (in Al as a model system), restoration of loop microstructure and dislocation/loop interaction in zirconium.

D. Caillard, M. Legros, F. Mompiou

In situ deformation in a TEM

In situ deformation or heating experiments in a TEM are mainly performed on the JEOL 2010 HC (200kV, Lab6) of the laboratory, while some more specific experiments (indentation, coupling with ASTAR) are performed on the I2TEM (300kV, Cold FEG) or the CM20F (200kV, S-FEG)

3 types of sample holders are available:

– Tensile specimen holders (without load cell):

– MEMS sample holders: on the JEOL (Hummingbirds, 7 contacts)

– Nanoindentation:

Micromechanical tests

These tests have the particularity to be performed in a SEM or a TEM.

-TEM: The deformation tests in in-situ TEM are one of the historical specialties of CEMES and of the PPM group in particular. They consist in deforming a thin foil inside a TEM and observing the mechanisms involved. By combining in-house and commercial holders, we can perform in situ tractions from 100 to 1700K on rectangular micro-tubes (1x3mm) thinned in their center, often by electrolytic polishing. A nano-indentation holder is also available on the I2TEM which allows to perform compression and traction on nano-objects using mechanical micro-devices. This holder is for the moment the only one that allows to measure the force applied during the test.

We are also trying to develop a device to measure force and displacement during an in situ TEM test using MEMS (Micro ElectroMechanical Systems) in which these two parameters are measured by capacitive devices.

-SEM: SEM deformation tests (nanoindentation, traction, compression) are now routinely performed on a FemtoTools FT-NMT04 system (the device replaces a custom setup based on D. Gianola’s at UPenn (Ref). The accessible forces are down to a tenth of a Newton, with noise in the nN range for the most accurate cells. The piezo movements are also controllable from a single software. We can therefore routinely perform compression tests on micro-pillars, bending tests on micro-beams (both machined by FIB) and obtain “mechanical maps” from nano-indentation fields.

Macroscopic mechanical tests

– A 30 kN Zwick tensile machine used at room temperature

– A high temperature creep machine (up to 800° C)

Orientation maps

Crystal orientation mappings are an essential element of physical metallurgy, especially to understand the plastic behavior of a polycrystal. We use electron microscopy to acquire them: EBSD (Electron Back Scattered Diffraction) in a SEM and ACOM*-ASTAR from Nanomegas for TEM samples. The latter technique allows the indexing of grains as small as the size of the probe used, i.e. a few nm in a FEG-MET.

*Automated Crystalline Orientation Mapping

Chemical mapping

The chemical mapping carried out in our studies on nickel-based superalloys allows to correlate the deformation mechanisms and the “local chemistry” of the alloys. TEM chemical analysis techniques (EDX and EELS spectroscopies) are used to obtain chemical maps at the nanoscale.

In the case of mechanical tests in conditions close to the real conditions of use during which the alloys undergo sometimes complex heat treatments, it is important to analyze the possible evolutions of local chemical composition. The scientific objective is then to identify and quantify if an evolution of the local chemistry has repercussions on the macroscopic behavior of the studied alloys.

Image: TEM image of a nickel-based superalloy and TEM-EDX mapping. C. Marcelot.

Machine Learning

The study of the dynamics of dislocations in-situ in TEM generates a large quantity of image sequences. For the moment, only human experience allows us to visually isolate the movement of these defects which appear with various contrasts. The manual quantitative analysis that we do from these images is very time consuming and potentially leads to statistical biases by sampling part of the data and averaging the quantities. We are currently working on an approach combining machine learning and computer vision methods to derive characteristic parameters of dislocations (local curvatures, pinning distributions, growth…) during their dynamics. The obtained data should allow a closer dialogue with numerical simulations, in particular at the mesoscopic scale.

labex project NanoX Distrack

DIC

Local deformation measurements can be made accurately by counting the mobile dislocations that cross a given area. This is possible with in situ TEM. However, when this is not possible (scanning electron microscopy, grain boundary movements, …) we can estimate these local deformations by DIC (Digital Image Correlation) on dynamic sequences. For this, we use an open source code: OpenCV, which we try to couple with other techniques such as orientation mapping (ACOM-ASTAR, EBSD) or obtained by other microscopies (AFM for example).

Find some examples of our in-situ videos on our YouTube channel.

…

0