How a combination of microscopy techniques solves an old metallurgical question

December 1, 2024

One of the solutions for drastically reducing the environmental impact of aero-engines is to introduce TiAl alloys into the stages of turbojet engines operating at over 800°C, due to the low density of these materials. The looked-for resistance to these high temperatures can be achieved by introducing heavy elements that will lead to the formation of a βo phase with an ordered, centered cubic structure. The TNM alloy belongs to this class of strong alloys, but suffers from very low ductility, making it impossible to industrialize.

As part of an international ANR project, CEMES researchers worked with their Austrian colleagues, the inventors of this TNM alloy, to understand the reasons for its premature fracture during a deformation cycle. To detect the origin of this effect, it was necessary to combine several techniques of electron microscopy, taking them to extremes.

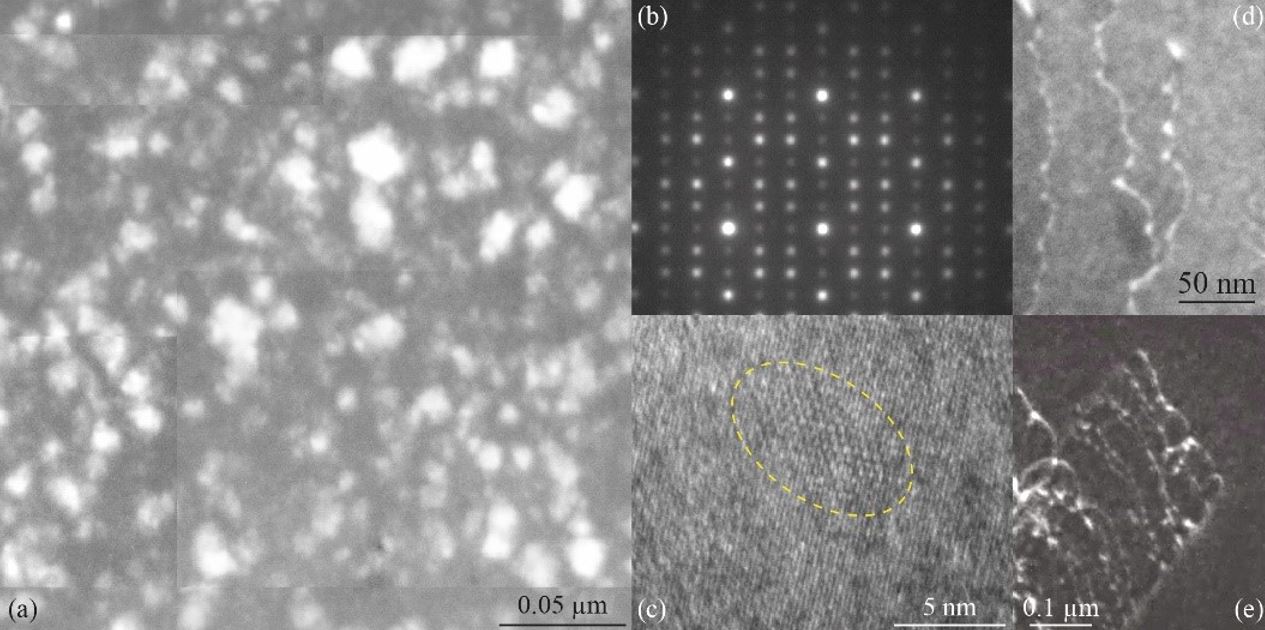

View (a) of the figure below shows that the ωo phase contains a second phase which appears in the form of diffuse nanoprecipitates. The low contrast results from the small difference in chemical composition between these two phases. These results, combined with zone-axis diffraction patterns (b) and high-resolution images (c), showed that these precipitates took on a ωo structure and were needle-shaped with characteristic dimensions of the order of a few nanometres.

In-situ deformation experiments, a technique that enables the

deformation mechanisms to be observed directly under stress, showed that although they represent a hardening obstacle to deformation (d), these precipitates can be crossed by dislocations and are therefore not directly responsible for the failure of the alloy. On the other hand, as shown in view (e), dislocations will form pile-ups of hundreds of dislocations to cross the precipitates, thereby creating stress concentrations that will ultimately lead to material failure.

These nanoprecipitates are therefore indirectly responsible for the premature failure of the material.

Analysis of the structure and characteristics of nano-precipitates of ωo phase in the TNM alloy. (a) dark-field image, (b) diffraction pattern in zone-axis, (c) atomic resolution image of a nanoprecipitate, (d) dislocations anchored on nanoprecipitates, moving during an in situ deformation experiment and (e) head of a dislocation pile-up.

Contact:

Alain Couret | alain.couret[at]cemes.fr

Publications:

Plasticity and brittleness of the ordered βo phase in a TNM-TiAl alloy

Molénat G., Galy B., Musi M., Monchoux J.P., Toualbi L., Clemens H, Thomas M., and Couret A.

Intermetallics 151, 18, 2022

DOI: https://doi.org/10.1016/j.intermet.2022.107653

ω precipitation and its influence on the deformation mechanisms of a TNM Ti-Al alloy

Molénat G., Monchoux J.P., Warrot-Fonrose B., and Couret A.

Materials Characterisation 218, 114509, 2024

DOI: https://doi.org/10.1016/j.matchar.2024.114509