The simplified elucidation of deformation mechanisms inspires new alloy designs

October 19, 2023

Elucidating the deformation mechanisms at the nanometric scale is often decisive in the design of new alloys. Controlling the deformation mechanisms at high temperature of the TiAl intermetallic would allow, for example, high-potential alloys for the aerospace industry to be developed. For this purpose, recent results from CEMES in Toulouse and CINaM in Marseille show that emerging approaches of electronic tomography are highly promising.

The deformation mechanisms at high temperature in metals, far from being fully understood to date, could be elucidated with greater ease thanks to three-dimensional reconstruction approaches. In the case of TiAl, this could be particularly attractive to inspire the design of new alloys, in the race to lighten hot parts in aircraft engines. The challenge would be to limit the movement of linear crystalline defects that control the undesirable deformation of the parts, namely dislocations.

To achieve this, it is necessary to determine whether the movement of the line of these defects takes place by successive jumps in the crystalline potential (glide), or by vacancy trapping (climb), in order to select the alloying elements that most effectively slow down these mechanisms. However, conventional transmission electron microscopy (TEM) methods are highly restrictive when it comes to identifying glide or climb, as the sample holders limit the observation of dislocations to a restricted angular range.

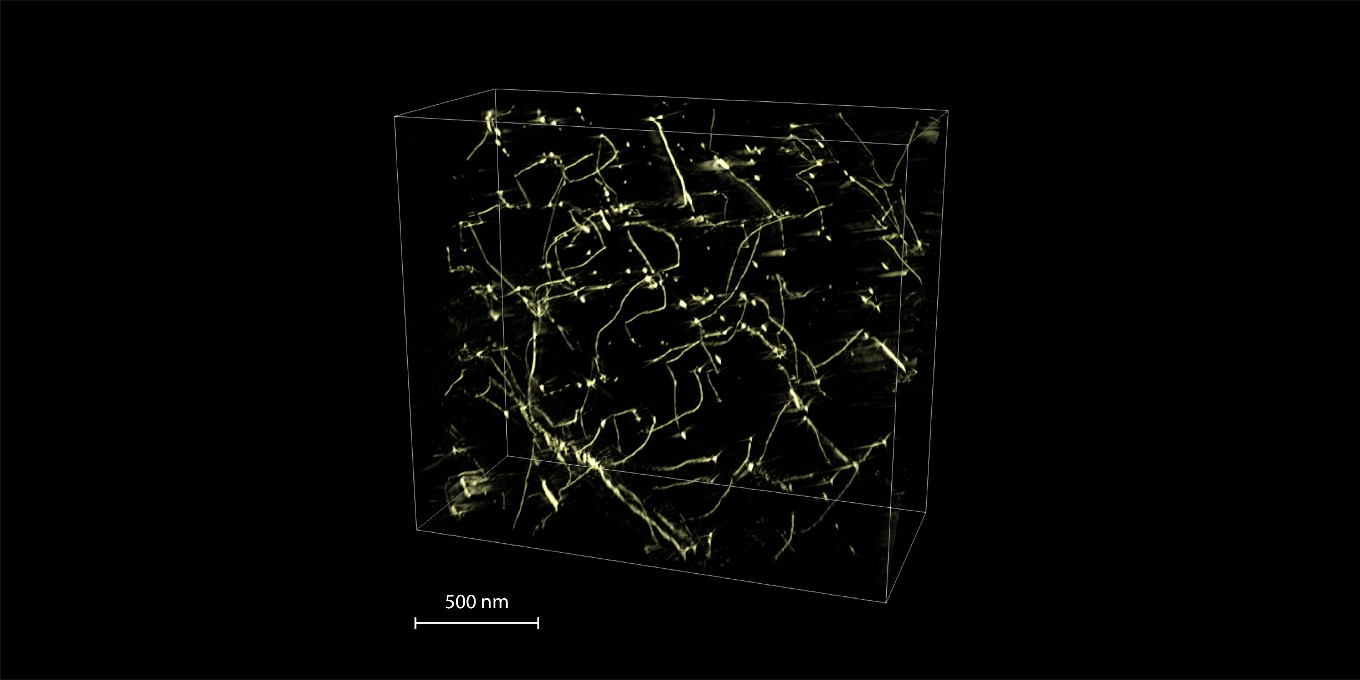

Electron tomography, by enabling 3D reconstruction of nanometric volumes and their 360° visualization, has spectacularly removed this obstacle. This technique first appeared in 2006 for the delicate observation of dislocations, and was subsequently taken up at the UMET of Lille by A. Mussi, but the teams at CEMES and CINaM have developed an original approach, enabling to go down to ultimate lateral resolutions (10 nm).

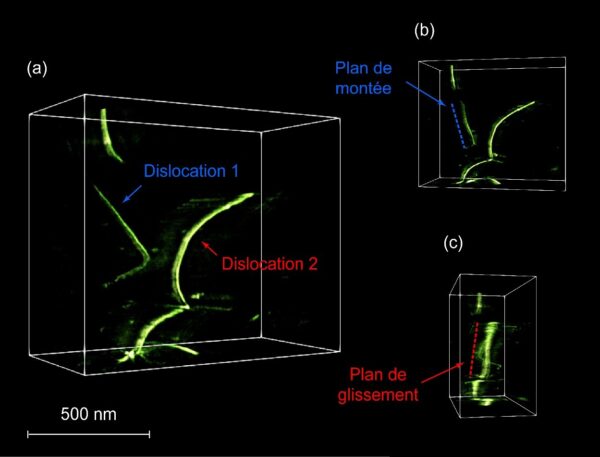

To achieve such high-precision tomographic reconstructions, the key step was to align series of up to 100 images around a common tilt axis, with sub-pixel precision. The idea was to adapt landmark recognition and tracking techniques, coming from the life sciences, to image alignment by successive iterations. This makes it possible to orientate dislocation displacement planes in space easily and with great precision, and thus to identify climb or glide mechanisms (cf. Figure 1).

Thanks to this type of observation, it will be possible to select the alloying elements that slow down dislocations motion most effectively, such as tungsten and molybdenum for climb, or carbon and silicon for glide. 3D vision is therefore particularly promising for furthering the design of new alloys, by enabling much more systematic investigations.

Fig. 1. Elucidation of deformation mechanisms in TiAl at 900°C, thanks to 360° 3D vision. (a) Volume of nanometric dimensions containing two dislocation loops. (b-c) Visualization of the volume from different angles, allowing to identify crystallographic planes of climb and glide for these two dislocations.

Publication:

Habit planes of climbing and gliding dislocations in TiAl determined in three dimensions by electron tomography

J.P. Monchoux and D. Ferry

Scripta Materialia 236 (2023) 115679

https://doi.org/10.1016/j.scriptamat.2023.115679

Contact:

Jean-Philippe Monchoux | jean-philippe.monchoux[at]cemes.fr